Table of contents:

-

Reassessing Priorities in a Shifting Landscape

How uncertainty is pushing companies to favor flexible, low-risk automation. -

Rethinking Inventory: From Just-in-Time to Just-in-Case

Why handling more inventory requires smarter use of space and better system control. -

Supply Chain Diversification and Flexibility

What shifting supplier networks mean for warehouse workflows—and how software keeps up. -

Staying Resilient Starts with Smarter Systems

A software-first approach to adapting fast, cutting costs, and scaling with confidence.

Tariff changes aren’t just shaking up global trade—they’re hitting the warehouse floor. As new tariffs roll out, companies face a cascade of tough decisions: Should we rethink sourcing strategies? Rebalance inventory levels? Hit pause on capital investments?

The changing environment highlights the importance of intelligent automation. Companies that have already embraced it are staying leaner and adapting faster with less friction. Here’s how automation keeps operations steady despite the global market disruptions.

1. Reassessing priorities in a shifting landscape

How intelligent automation helps:

AI-powered automation becomes a real asset during periods of market disruptions. Intelligent software such as inVia Logic WES gives real-time control over workflows and detailed oversight of inventory and processes. This means businesses can quickly shift labor and inventory strategies, even as plans evolve. inVia’s Twin IQ intelligent warehouse simulation additionally allows companies to model different scenarios before making changes. They can test new workflows in just minutes to evaluate cost impacts and make smarter decisions without disrupting operations. It gives teams the confidence to adapt with precision, even when the path forward is uncertain.

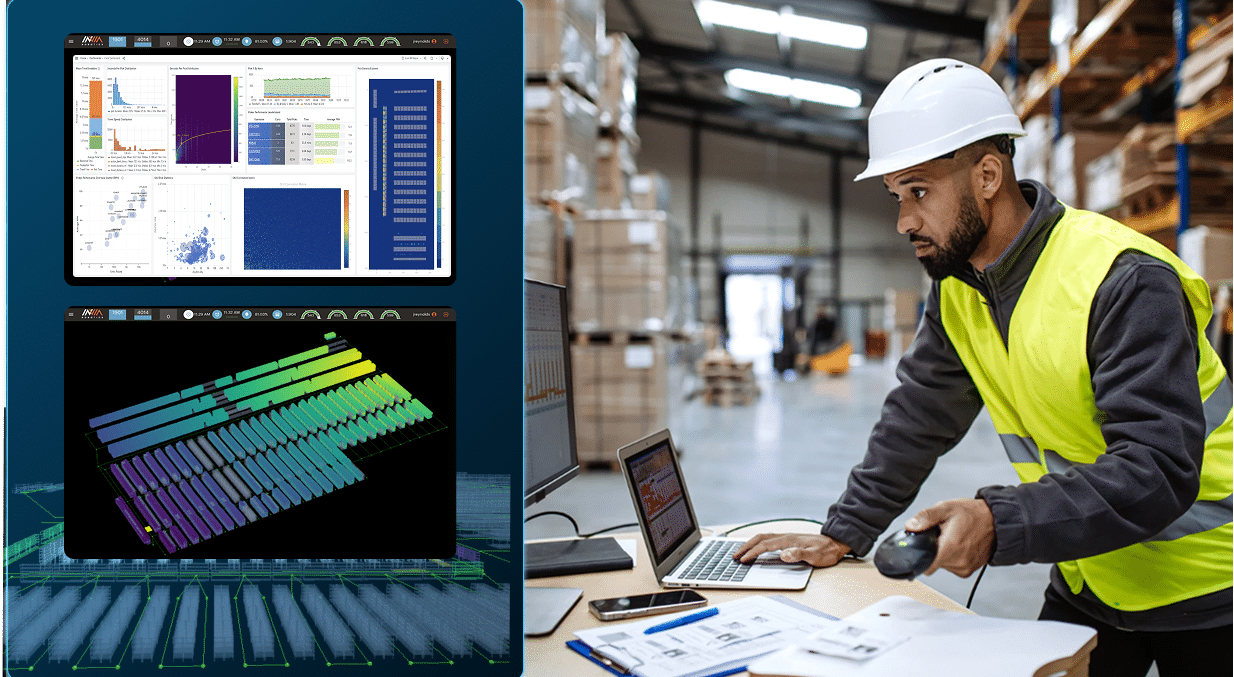

AI-powered inVia Logic WES and Twin IQ Warehouse Simulation Software

2. Rethinking inventory: from Just-in-Time to Just-in-Case

To avoid delays or price hikes, more companies are stocking up—moving from just-in-time to just-in-case inventory. This means building up larger stock reserves in domestic warehouses. But stockpiling comes with trade-offs: mainly the strain it puts on warehouse space, labor, and systems that were initially designed for leaner operations.

How intelligent automation helps:

To manage this shift, leading distribution centers are rethinking how inventory is stored, tracked, and replenished. The focus is less on physical expansion but more on intelligent optimization to find ways to use existing space more effectively and keep inventory accessible without overwhelming workers or systems. And since keeping costs down is essential, intelligent software automation becomes a practical, scalable solution that delivers immediate impact without major infrastructure investments.

inVia’s software-first automation approach is built for this kind of challenge. It offers multiple ways to support high-volume inventory strategies without costly infrastructure changes:

- SKU Optimization with Twin IQ Simulation: Twin IQ gives operations teams the ability to test different slotting strategies in a digital twin of their warehouse. AI models recommend changes – like repositioning high-volume SKUs for faster access – that can boost efficiency without touching the physical layout.

- Dynamic Inventory Placement Across the Warehouse: inVia Logic WES uses real-time order and inventory data to find the best storage locations. The system dynamically allocates SKUs based on product velocity, zone rules, and availability, helping make better use of space while reducing travel time.

- Real-Time Visibility and Control: With detailed insight into inventory levels and movement, managers can make better decisions about what to stock, where to store it, and when to reorder.

inVia Logic Intelligent Inventory Placement

3. Supply chain diversification and flexibility

In response to shifting tariffs, many companies are diversifying their supplier base—sourcing from new regions or reshoring operations entirely. These changes improve resilience, but they also introduce new complexity: unfamiliar packaging types, fluctuating lead times, and different product flows that distribution centers must quickly adapt to.

How intelligent automation helps:

As supplier networks shift and product mixes evolve, distribution centers need systems that can adapt just as quickly. Intelligent software provides the flexibility to adjust operations in real time without disruption or costly delays.

inVia’s software-first automation approach helps companies stay flexible and responsive:

- Workflow Flexibility with inVia Logic WES: Intelligent WES software sifts through massive amounts of data and learns quickly to optimize performance. When new products, packaging, or fulfillment strategies change, inVia Logic updates workflows without reprogramming or downtime. The system continuously analyzes inventory, labor, and order data to optimize task distribution and pick paths as conditions change – no manual recalibration required.

- Cost-to-Fulfill Insights: inVia’s Business Intelligence tools highlight which SKUs or product categories are the most expensive to fulfill. This visibility helps you make faster, smarter decisions about what to scale and which business lines may no longer make financial sense.

- Inventory Placement Optimization: When product types or packaging changes, your inventory strategy needs to change too. inVia Logic dynamically adjusts inventory placement to make sure new SKUs are accessible and efficiently located.

Staying Resilient with Smarter Systems

Tariff changes and shifting supply chains are pushing distribution centers to adapt faster than ever. But with the right tools in place, uncertainty becomes a chance to operate smarter. From rethinking inventory strategies to adapting to new supplier flows, intelligent software like inVia Logic and Twin IQ helps businesses stay agile, efficient, and in control.

Want to see how AI can improve your warehouse?

Request a demo to speak to our experts!