It comes as no surprise to the team at inVia Robotics that our autonomous mobile robots are the part of our warehouse solution that generates the most excitement and attention. We don’t blame anyone for this—we still get a little excited ourselves when we watch our fleet in action, whirring quickly and easily across the aisles, bringing goods to their designated picking station, saving our clients and their people time and money.

They are, inarguably, the coolest component of our solution. But they are not the whole story.

The promise of more efficient, speedy, productive warehouse operations is also fulfilled by inVia’s software, not just our hardware. Our automated storage and retrieval system (AS/RS) integrates seamlessly with any warehouse management software (WMS)—from big-name players like HighJump and Manhattan Associates to Microsoft Nav and proprietary systems.

“How” we do this is as important, and inextricably tied to, “why” we do it this way. We use a RESTful API—a common, almost de facto internet standard that presents data and information the way a user is accustomed to seeing it—to make this process clean and easy for our customers. We designed this service to have a well-supported, well-documented, well-tested RESTful API, and as a result, you can interface with our system using any programming language, with all the features you’d expect from a first-class system, including filtering and sorting. Depending on experience, needs, and comfort level, customers can integrate with our API directly, or our team of integration specialists can design a process, a thin “integration layer,” to ensure your software interface lines up with our system.

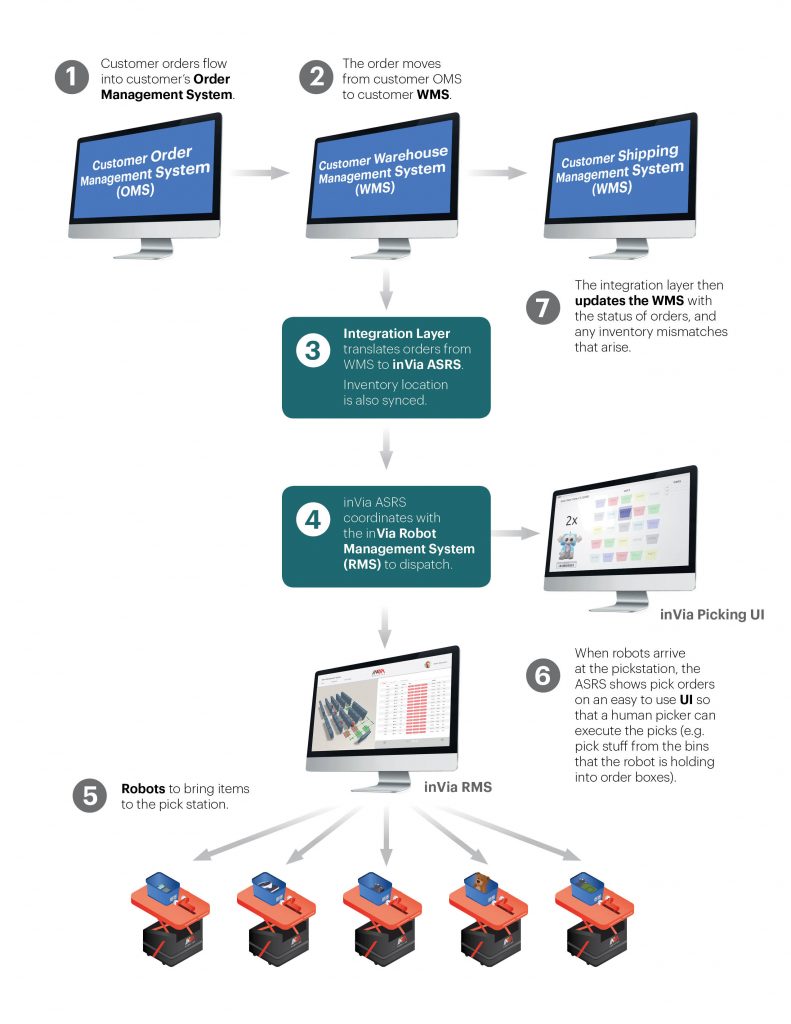

Now, that all sounds good for as much as you can understand internet software-speak, so let’s break this down with an example. Let’s say a customer orders four t-shirts. That order line flows from your order management system (OMS) to your WMS of choice—in this instance, we’ll use HighJump. The integration layer our team implements allows HighJump to translate that order to inVia’s AS/RS, while syncing inventory data across the systems so that we know where each item in your warehouse is, and how many are left.

From there, the inVia solution takes over. Our AS/RS dispatches our fleet of robots to travel the warehouse floor to retrieve the bin containing the four t-shirts, and deliver them to the picking station. The inVia system shows the pick orders on an easy-to-use UI, so that a worker can execute the picks—in this case, select the four t-shirts from the bin and place them in the appropriate order box. Our integration layer updates your WMS with the status of the order, as well as any inventory mismatches that arise, which our system will triage automatically (e.g., pulling merchandise from another location in the warehouse).

With all the order data being converted to our system, we can report any level of data analysis for you at any time, from tracking order details to robot productivity. And this is all without having to re-train your employees on a new software system.

That’s why we designed our solution using RESTful APIs. It aligns with today’s trends, job market, and workforce education (and comfort). This contributes to a far smoother, quicker deployment period, while also not disrupting your company’s own onboarding process for new warehouse employees.

We’re here to enhance and improve your warehouse employees’ day-to-day job function, from pickers to your in-house IT staff. By empowering your IT team with all the information they need on a system they’re familiar with, we’re not just making their jobs easier—we’re making them better.

Ready to learn more about how inVia Robotics’ AS/RS can work seamlessly with your WMS? Reach out to our sales team for more information on how we can enhance your warehouse operations today.