Table of contents:

- The Complexity of Warehouse Integration

Why fragmented systems and new automation tools are making IT’s job harder. - What IT Actually Needs

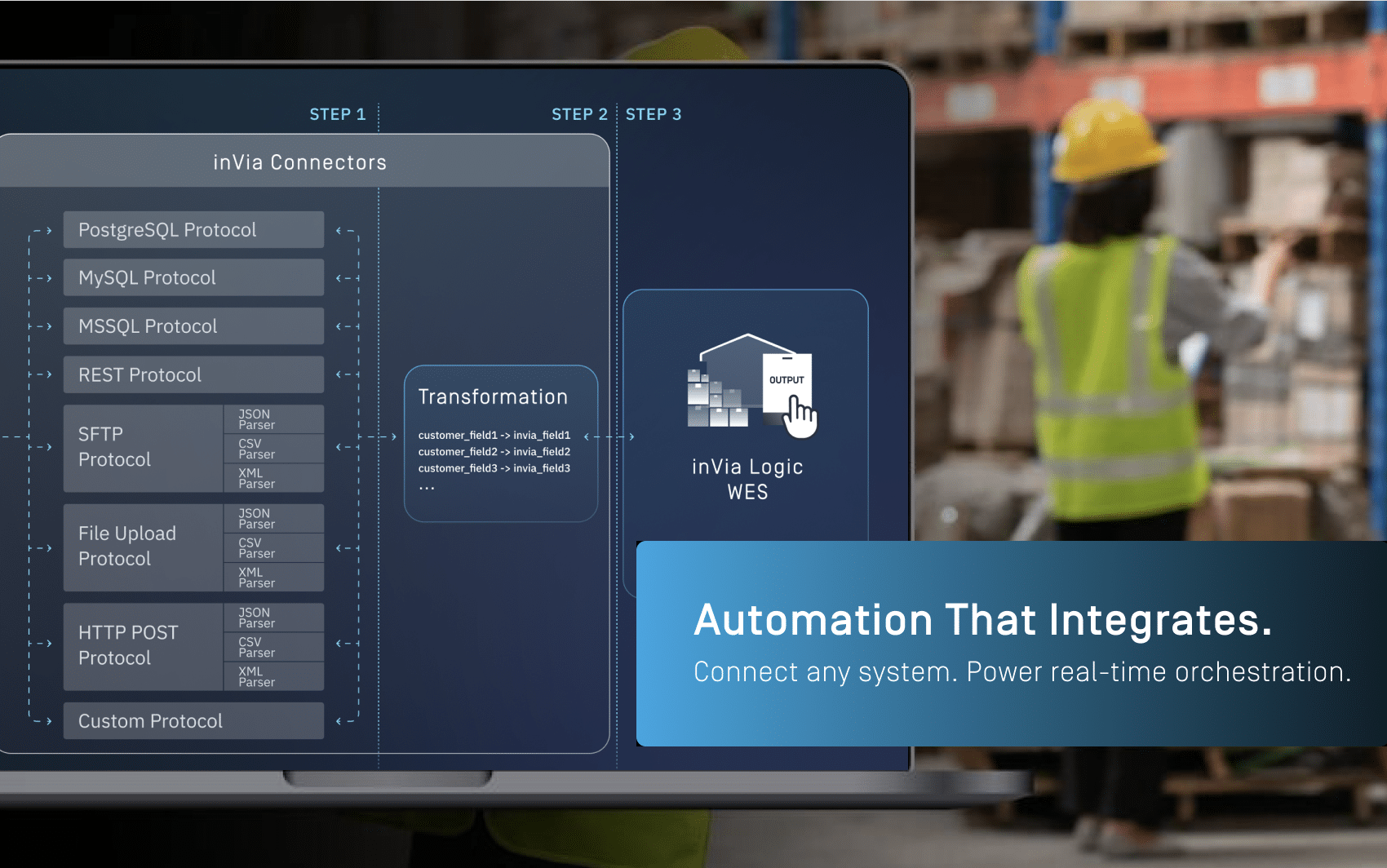

Key requirements for fast, low-risk automation that fits your existing stack. - How We Built It Into inVia Connect

A behind-the-scenes look at how we designed our integration layer for flexibility and control. - Conclusion: Integration Without the Headaches

How inVia Logic WES and inVia Connect simplify automation without adding complexity.

IT teams are under constant pressure to lead and support the push for warehouse automation, real-time analytics, and system modernization. But behind every successful upgrade lies a challenge they’re all too familiar with: integration.

In today’s distribution centers, core systems like the WMS, ERP, and OMS weren’t built to work together. As companies adopt automation platforms like inVia Logic WES to orchestrate workflows, optimize labor, and improve fulfillment speed, IT must connect it all fast, accurately, and with minimal disruption. It’s a constant cost-benefit tug-of-war, balancing innovation with stability, and speed with risk.

Recognizing the need for a solution that could bridge systems without requiring a complete rewrite, our team built inVia Connect—a flexible, vendor-agnostic integration layer that fits into your existing tech stack, supports a wide range of protocols, and transforms data in real time, all without adding unnecessary burden to your team.

1. The Complexity of Warehouse Integration

Modern distribution centers run on a stack of systems—WMS, ERP, TMS, OMS—each designed for different functions, often built by different vendors, and rarely speaking the same language. Every system comes with its own data formats, communication protocols, and update cycles. Some still run on legacy infrastructure that was never intended to integrate with modern tools. Others evolve frequently, forcing IT to constantly rebuild fragile connections just to keep operations running. To bridge these gaps, IT teams often rely on patchwork solutions: custom scripts, manual data uploads, brittle APIs. These makeshift fixes might work temporarily, but they don’t scale—and they rarely hold up under change.

And now, as businesses introduce warehouse automation and robotics into the mix—AMRs, AS/RS systems, goods-to-person workstations, and sortation systems—the complexity multiplies. These technologies often come with their own interfaces, data models, and timing expectations, making integration even more fragile. Even small automation projects become high-risk when integration isn’t flexible or resilient. The more systems involved, the more brittle the architecture becomes—and the more likely it is to break under pressure.

Warehouse Execution System (WES) software is emerging as a critical layer for bridging the gap between upstream business systems and the execution floor. But for many solutions, integration remains the biggest weakness—making deployments slower, riskier, and more resource-intensive than they should be.

That’s why the inVia Logic warehouse intelligence platform is a strong ally for IT teams. Beyond its real-time orchestration capabilities, it’s built on a solid integration foundation: inVia Connect.

AI-powered inVia Logic WES and Twin IQ Warehouse Simulation Software

2. What IT Actually Needs

For IT leaders, automation can feel like just another integration problem waiting to happen. Our own technology team recognized this early on. Through close collaboration with customers and partners, we gained a clear understanding of what IT teams actually need when deploying new systems:

-

Speed and ease — Integration is often the hardest, most time-consuming part of any automation rollout. Long timelines and brittle workarounds stall progress. IT needs solutions that are quick to configure and don’t require weeks of custom coding.

-

Flexibility to integrate with any system, in any environment — Whether it’s a legacy WMS or a modern cloud ERP, the integration layer should adapt, not the other way around.

- Support for a wide range of protocols and formats — REST, FTP, SQL, SFTP, CSV, JSON, warehouses run on all of it.

-

A clear path for configuration and monitoring — Integration shouldn’t require constant developer involvement. IT teams want tools they can monitor and manage without touching the codebase every time something changes.

In short: faster integration, fewer surprises, and no added burden.

3. How We Built It Into inVia Connect

When we built inVia Connect, we weren’t just trying to link systems. We were solving the integration challenges that delay automation and drain IT resources. The goal was to create a layer that’s as adaptable as it is stable, one that plugs into your existing environment, speaks your protocols, and doesn’t slow your team down.

Here’s how we made that possible:

- Protocol and Format Flexibility

inVia Connect supports a wide range of integration methods that can be mixed and matched to fit your stack. Want to send orders over HTTP, receive inventory updates as a CSV drop via FTP, and write pick results back into a MySQL database? No problem. inVia Connect supports whatever combination your environment requires—no rework needed.

- Flexible Data Mapping

You don’t need to change upstream systems. Our advanced templating engine can rename fields, restructure payloads, and reformat data without requiring modifications to your WMS, OMS, or ERP.

- Fault-Tolerant Message Queuing

If a connection between inVia and your system goes down, fulfillment continues uninterrupted. Messages are automatically queued and delivered once connectivity is restored. Built-in monitoring and alerting give your team visibility into queue depth and message flow—so you’re never in the dark.

inVia Connect: Vendor-agnostic integration tool

Conclusion: Integration Without the Headaches

Warehouse automation shouldn’t come at the cost of complexity. For IT teams, the challenge isn’t just adding new tools—it’s making them work within a tech stack that’s already under strain.

inVia Logic WES delivers the orchestration layer modern warehouses need. But what makes it truly IT-friendly is the integration architecture beneath it. inVia Connect was purpose-built to simplify how systems talk to each other—so you can move faster, deploy smarter, and support innovation without creating new points of failure.

Automation doesn’t have to mean disruption. With the right integration layer, it becomes an upgrade—not a rebuild.

Want to see how AI can improve your warehouse?

Request a demo to speak to our experts!